Enhancing OEE & reducing

failures with a CNC and machine

tooling health monitoring solution

Customer Background

Our customer has been a trusted name in industrial automation for more than two decades. Based in the US, they deliver comprehensive machine tool solutions—including electrical, hydraulic, lubrication, sealing, and mechanical systems. With a global network, they are known for delivering reliable, high-performance solutions that precisely fit their customers’ needs.

Customer Need

As part of the customer’s vision to evolve into a smart manufacturing enterprise, they sought to modernize their operations and build an on-premise CNC and machine-tooling health monitoring system. Their goal was to achieve real-time visibility into machine performance, improve operational efficiency, track OEE, and establish a strong foundation for future smart factory initiatives.

Softdel’s deep expertise in Industry 4.0 and factory automation—combined with our successful track record in delivering similar on-premise monitoring solutions and large-scale deployments for leading global clients—positions us as the ideal strategic partner to drive this transformation.

Softdel’s Solution

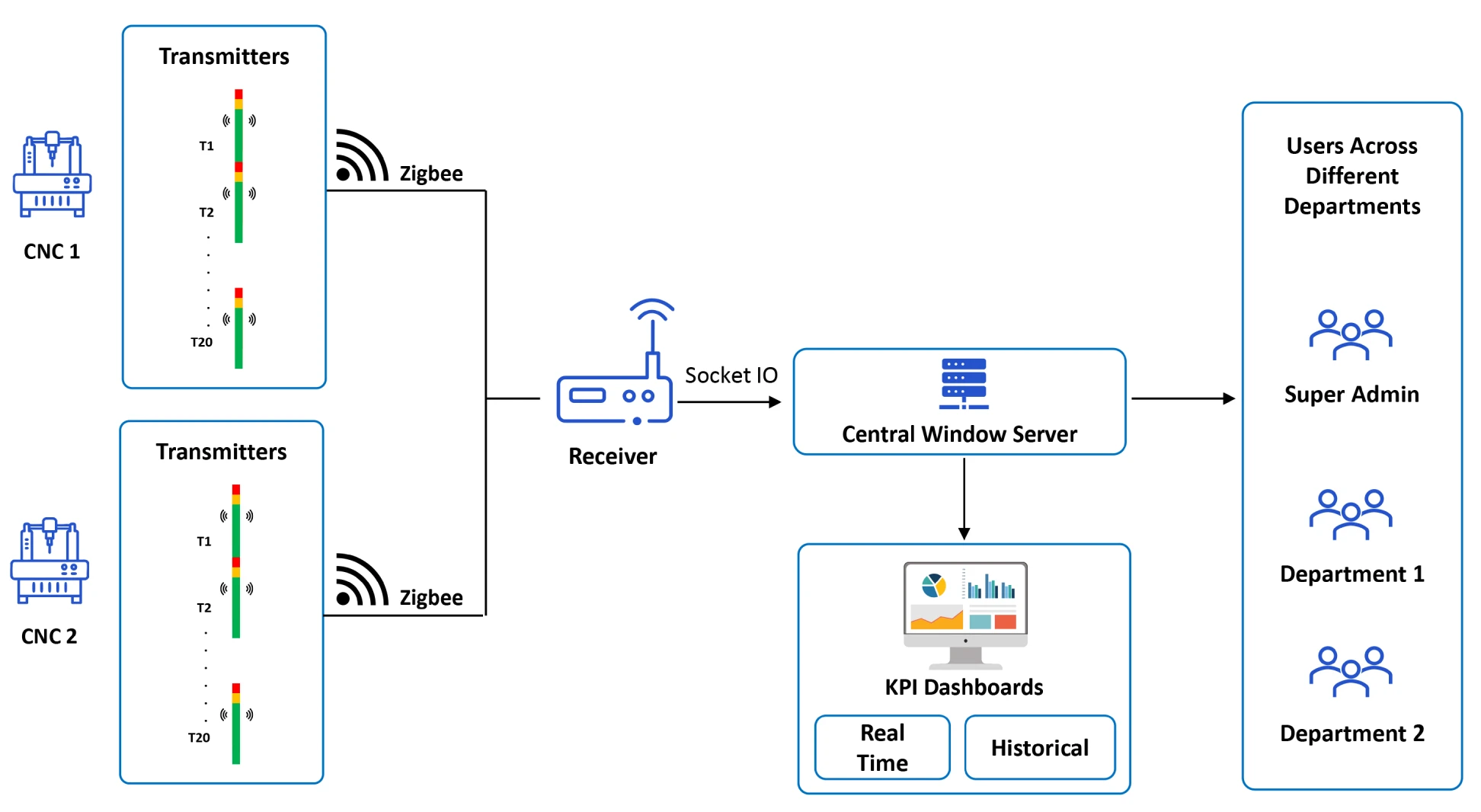

- Softdel developed a highly scalable and resilient on-premise application designed for real-time data acquisition, machine performance monitoring, and actionable operational intelligence. Engineered to support continuous manufacturing environments, the solution enables real-time visibility, role-based insights, proactive maintenance, and secure data management—all within a robust microservices-driven architecture.

- Key components and features of the solution included:

- Backend Architecture & Data Integration: A secure, microservices-driven backend hosted on a local web server, engineered to capture real-time data from the CNC machine, transmitted via the Patlite WD transmitter. These signals are processed through a structured data pipeline for validation and transformation, enabling accurate operational insights. The backend exposes this data via REST APIs to the frontend for real-time machine status visualization and performance monitoring.

- Application Features

- Web-responsive, cross-browser UI built using structured design and wireframes

- Real-time machine status views with historical trend analytics

- Centralised, department-wise dashboards designed to bring all machine insights together in one place, with multi-role access (Admin, Supervisor, Operator, Viewer) and configurable thresholds

- KPI-driven insights including uptime, downtime, alarm frequency, cycle performance, and OEE indicators

- Customizable alerts for machine conditions, failures, and time-based triggers

- Automated SMS and email notifications sent to predefined contacts for alarms and maintenance events

- CSV exportable reports with over three years of operational data

- Preventive Maintenance

- Intelligent reminder system configurable by fixed dates, recurring intervals, or accumulated operating hours

- Automatic reset for hour-based maintenance cycles

- Predefined parts list for each asset, complete with e-commerce purchase links tailored to the specific machine configuration

- Security & Data Management Features

- Secure access mechanisms, including role-based user permissions, HTTPS-encrypted communication for all web interactions, and comprehensive license management (certificate handling, encrypted keys, tamper prevention, validation, and renewal)

- Localised data storage to ensure privacy and compliance

- Configurable data purging, archiving, and backup/restore processes

Standards and Technology

Interface: REST API

Communication Protocol: Zigbee

Frontend: Angular

Backend: NodeJS

Benefits

- 17% reduction in unplanned downtime: Continuous data capture and automated alerts have minimised unexpected machine stoppages, enabling maintenance teams to intervene more quickly and accurately.

- 10% increase in OEE: By bringing together real-time machine data and operational metrics, the solution supports clear visibility into availability, performance, and quality, resulting in a marked uplift in OEE by around 10%.

- Seamless scalability & future-readiness: Microservices architecture enables easy updates, feature additions, and potential migration to cloud, AI analytics, and OEE tracking when needed.

- Enhanced asset availability: The combination of real-time machine insights and one-click access to model-specific spare parts enables faster intervention and minimises time spent waiting for components, directly improving asset availability.