Configurable remote condition

monitoring application for a

range of oil debris sensors

Customer Background

Our customer, a reputed Canadian-based company, provides solutions for critical components of wind and gas turbines. The company has been operational for 40+ years, and consistently delivers the best-in-class diagnostic and prognostic technologies to help organisations across various industries like aviation, energy, mining, and more, support their equipment.

Customer Need

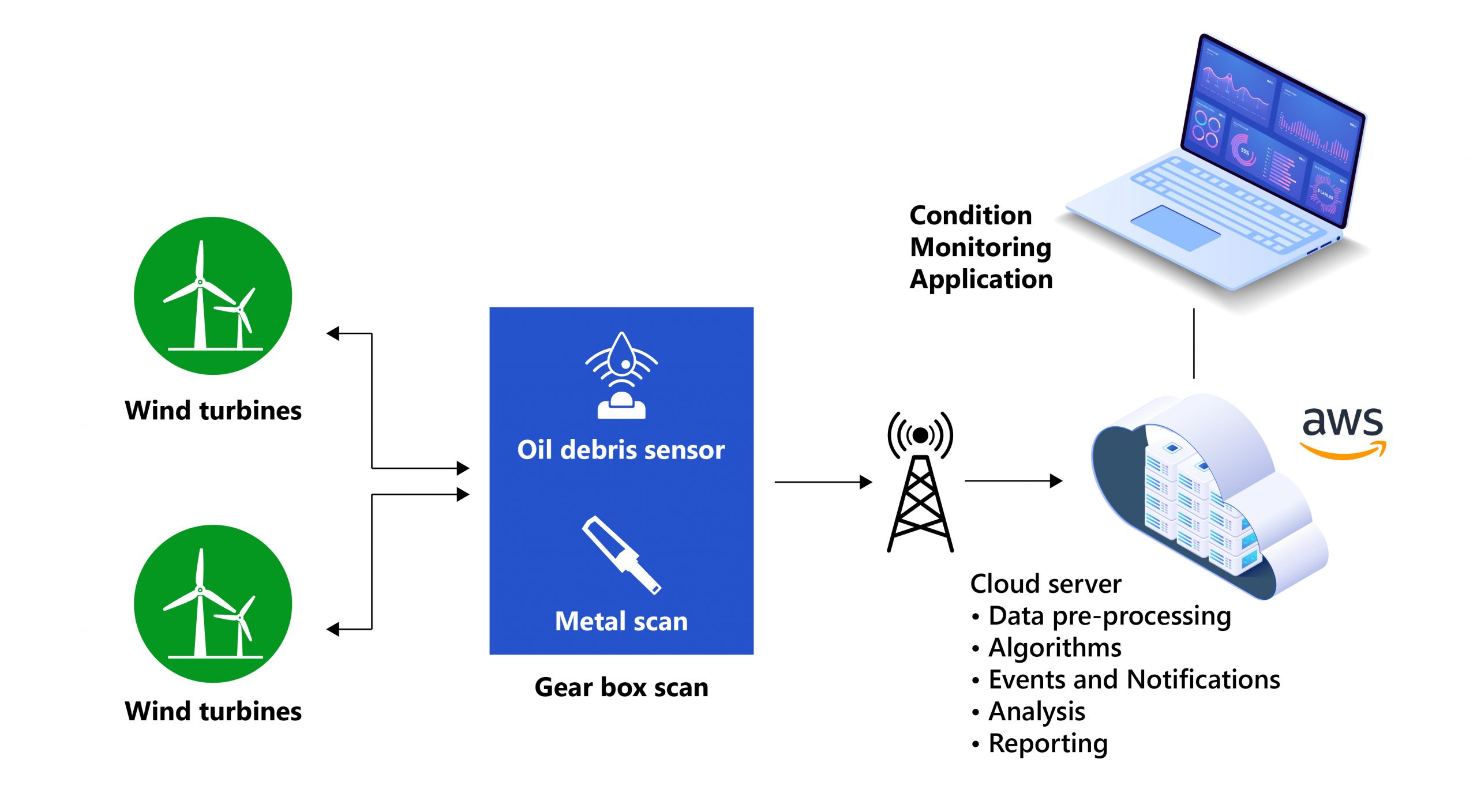

The customer’s product suite includes a wide range of equipment monitoring sensors that detect everything from oil debris to metal particles inside the gearboxes of wind turbines. They needed a cloud-based critical equipment condition assessment system for one of their flagship products, an oil debris sensor. The product is needed to efficiently detect debris in the gearbox oil of wind turbines operated by the customer, and would also have to be compatible with different gas and wind turbines. The customer approached Softdel to build this remote condition monitoring application.

Softdel’s Solution

- Softdel developed a configurable sensor-based condition monitoring application suitable for all types of oil sensor applications, that was hosted on the AWS cloud platform.

- The solution integrated REST API and the SSH File Transfer Protocol (SFTP) server to ensure easy data sharing with third-party applications.

- Support for reporting, data analysis, and chaining algorithms were implemented to enable effective predictive maintenance of equipment, as well as provide condition indicators.

- Softdel also equipped the solution with event notifications, personalised SMS, email and web-based warnings, and alarms, for further action.

Standards and Technology

Programming Language: React JS

Cloud Platform: AWS ECS, API Gateway

Database: AWS RDS Postgres, S3, Glacier

Script: Python

Benefits

- Efficient predictive and preventive maintenance: Softdel's solution provides accurate and instant information on component wear and tear that can even predict equipment failure ahead of time, helping the customer benefit from actionable insights.

- Operational excellence: The real-time equipment condition monitoring accessible from anywhere provides instant notifications about the health of the equipment, creating a three dimensional view of operations.

- Extensible application: The platform can easily be integrated with applications across the customer's product line, and also enables data-sharing with third-party systems for better interoperability.